DTS-210 Turbidity Analyzer

Turbidity Analyzer is an instrument used to measure the degree of turbidity in water bodies, quantifying water clarity by detecting the scattering or transmission effects of suspended particles in water on light. Its application areas and monitoring content are closely related to water transparency, particulate matter content, and water quality safety. Widely used in drinking water treatment and safety monitoring, wastewater treatment, environmental water monitoring, industrial process control, aquaculture and other fields.

Type:Water Quality Analyzer

Material: 316 Stainless Steel

Color: Silver sensor plus balck controller

Model:DTS-210+DMC210

OEM:Available

MOQ:1 set

Product Description:

About DMC-210 Display controller

Basic Function

1. Diverse languages, factory standard Chinese interface, switchable English interface

2.4-20mA output, using isolation technology, strong anti-interference ability

3. The high and low points of the three sets of relays can be switched freely, and the hysteresis can be adjusted freely to avoid frequent on-off of the relays

4. Password management function to prevent misoperation by non professionals

5. The menu prompt function greatly facilitates user operation

Instrument technical parameters

Temperature compensation: 0-100 ℃ manual/automatic

Signal output: 4-20mA isolated protection output, maximum load 500 Ω

Alarm output: Three groups can correspond to high and low point alarms (3A/250VAC) at will, with normally open contact relays

Power supply: AC220V or DC24V

Power consumption: ≤ 10W

Environmental conditions: (1) Temperature 0-50 ℃ (2) Humidity ≤ 85% RH

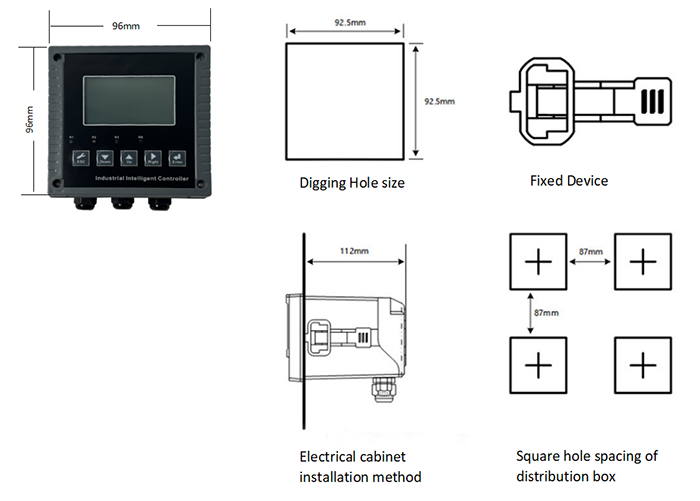

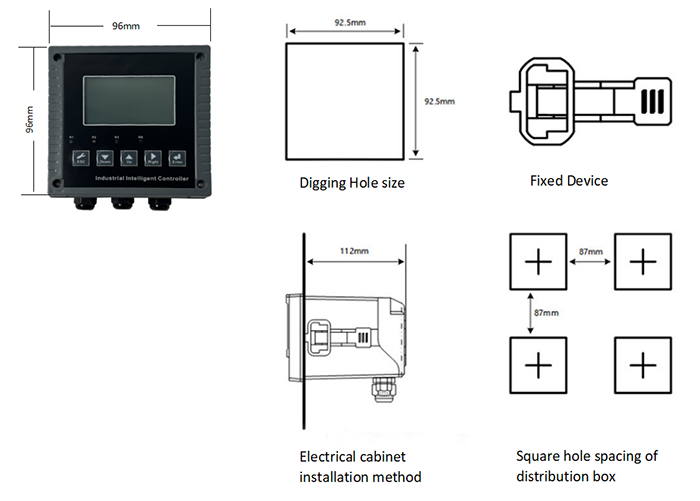

Dimensions: 96 × 96 × 132mm (height × width × depth)

Hole size: 92.5 × 92.5mm (height × width)

|

Name

|

Parameter

|

|

Power Supply

|

(Default)AC220V or DC24V(Optional)

|

|

Access Signal

|

The RS485 Digital signal sensor produced by the company supports MODBUS/RTU

|

|

Output Signal

|

4-20mA Isolation protection output,Maximum load 500Ω

|

|

Working conditions

|

Temperature 0-50℃ Humidity ≤85%RH

|

|

Level of protection

|

IP68

|

|

Service Life

|

2 years or more

|

|

Sensor housing material

|

PPS

|

About DTS-210 Turbidity Sensor

DTS-210 is a basic conventional water quality monitoring digital turbidity sensor; Adopting the mature 90 degree scattered light principle from abroad, using the design method of infrared LED light source and fiber optic transmission optical path; Internally added filter design, with strong resistance to external light interference. Built in temperature sensor with automatic temperature compensation, suitable for long-term online monitoring of environmental use.

characteristic:

1. Digital sensor, directly outputs Rs-485 digital signal, supports MODBUS/RTU

2. 90 degree angle scattered light principle, built-in temperature can automatically compensate;

3. Fiber optic structure with strong resistance to external light interference

4. Infrared LED light source, with added filter design, resistant to light source interference, and good stability

5. Surface anti-corrosion and passivation treatment

6. Low power consumption of sensors and anti-interference design of internal circuits

About DTS-210 Turbidity Sensor

DTS-210 is a basic conventional water quality monitoring digital turbidity sensor; Adopting the mature 90 degree scattered light principle from abroad, using the design method of infrared LED light source and fiber optic transmission optical path; Internally added filter design, with strong resistance to external light interference. Built in temperature sensor with automatic temperature compensation, suitable for long-term online monitoring of environmental use.

characteristic:

1. Digital sensor, directly outputs Rs-485 digital signal, supports MODBUS/RTU

2. 90 degree angle scattered light principle, built-in temperature can automatically compensate;

3. Fiber optic structure with strong resistance to external light interference

4. Infrared LED light source, with added filter design, resistant to light source interference, and good stability

5. Surface anti-corrosion and passivation treatment

6. Low power consumption of sensors and anti-interference design of internal circuits

|

Name

|

Parameter

|

|

Output Signal

|

Support RS-485,MODBUS/RTU Protocol

|

|

Measurement method

|

90°℃

Scattering light method

|

|

Range

|

0-200 NTU,0-1000NTU,or 0-3000 NTU

|

|

Accuracy

|

+-3% display value or +-2NTU,the largest (0-200NTU)

+-5% display value or +-3NTU,the largest(0-2000NTU)

+-5% display value or +-10NTU,the largest(0-3000NTU) +-3°℃

|

|

Defence rate

|

0.1NTU,0.1°℃

|

|

Working conditions

|

0-50°℃

,<0.6Mpa

|

|

Calibration method

|

Two point calibration

|

|

Response time

|

30 seconds T90

|

|

Temperature compensation

|

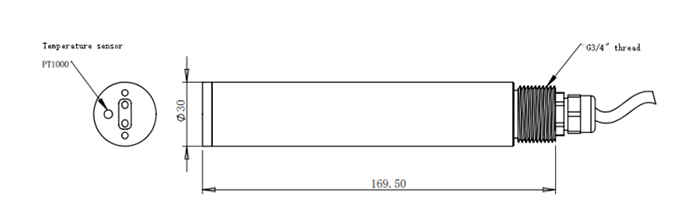

Automatic temperature compensation(PT-1000)

|

|

Power supply

|

12 or 24VDC,+-10%,10mA

|

|

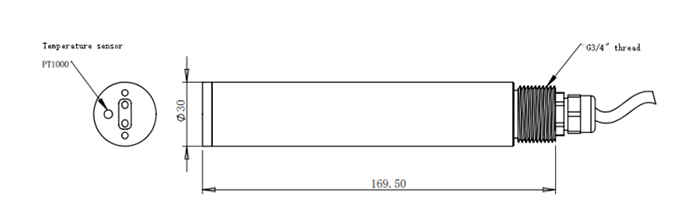

Measurement

|

Diameter 30mm,Length 169.5mm

|

|

Level of protection

|

IP68,water depth 20 meters

|

|

Service Life

|

Sensor 3 years or more,depends

|

|

Cable Length

|

10 meters(default),customizable

|

|

Sensor housing material

|

316 stainless steel or POM

|

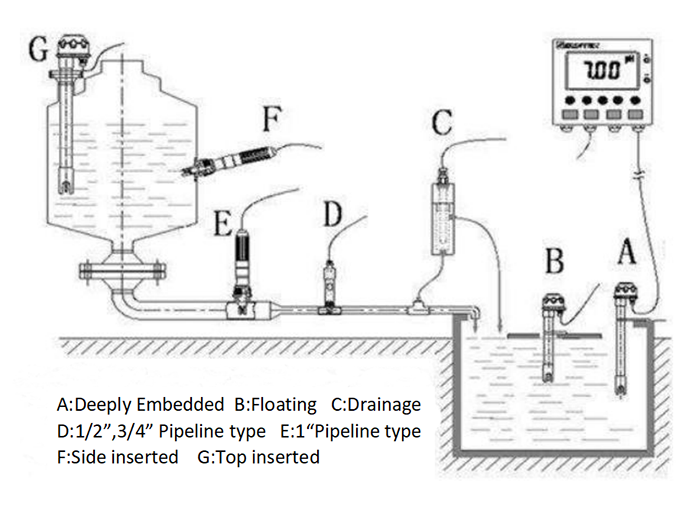

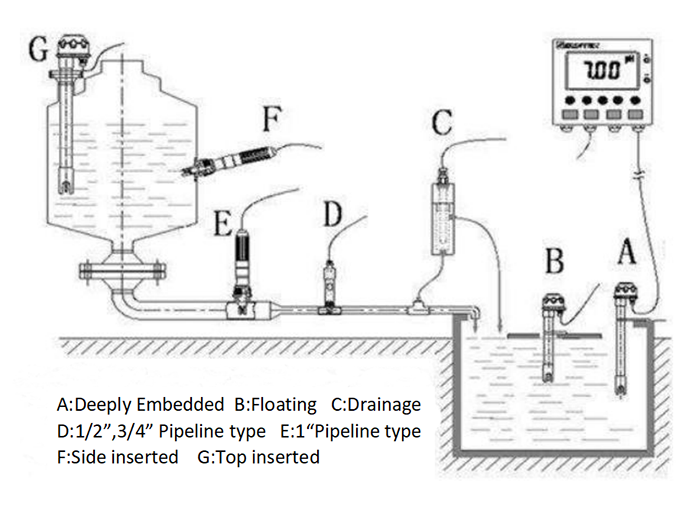

Installation:

Installation:

How to use Turbidity Analyzer?

Electrodes are very delicate components and must be installed correctly. Incorrect installation can lead to electrode damage or irreversible damage.

How to use Turbidity Analyzer?

Electrodes are very delicate components and must be installed correctly. Incorrect installation can lead to electrode damage or irreversible damage.

The sensor is installed in the area without slow water flow; the sensor is maintained 5 cm from the surrounding wall.

1. Maintenance:

It is recommended to clean the sensor every 30 days; avoid scratching the sensor during cleaning; please wipe with a soft wet cloth.It is recommended to clean the outer surface of the sensor with water flow. If there is still debris, wipe it with a wet soft cloth.

2.Installation measurement: Avoid installation measurement in the rapid current, and reduce the impact of current bubbles on the measurement. Keep the measuring probe 5 cm away from the bottom.Suggestion: Select the company protective cover to prevent microbial attachment from affecting the measurement results.

Logistics transportation:

FAQ:

FAQ:

Q1:Are you factory or trading company?

A: We are a manufacture with independent import and export rights.

Q2:How is the quality of your products?

A: Lotus is a manufacturer with production for more than 6 years,We have a complete production

management system and Independent laboratory for testing equipment with a high product

qualification rate .

Q3:How can I get the samples?

A: contact sales to get the samples

Q4:what’s the Minimum order Quantity and Payment?

A1: Payment:EXW,FOB,CFR,CIF,etc.

A2:Minimum:trial order is also available,but with sample price.

Q5:what’s your Lead time?

A: As the General size have stock with fast delivery,the customized size need to negotiate mostly

within 15days.